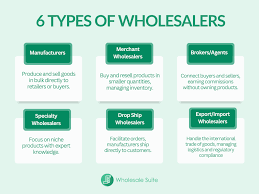

Why Wholesalers Give Importers Limited Flexibility in Product Choices

Importers often feel stuck with narrow product choices when buying from wholesalers. This locked-in approach risks missing market trends or customization opportunities. Still, wholesalers have clear reasons for running tight, focused catalogs.

Wholesalers restrict product options to keep inventory manageable, achieve economies of scale, and maintain fast turnover. This helps deliver stable prices and availability, though it limits importers’ ability to request custom or niche products.

I used to get frustrated when my wholesalers only offered a few core SKUs and refused to add anything new. Over time, I saw they could deliver on promises, hold enough stock, and keep prices steady, all because they focused. When I needed unique items, I learned to build relationships with smaller, flexible partners instead. It became clear that managing product choice is about balancing efficiency with agility.

What is a disadvantage of using a wholesaler distributor to distribute your products?

Why does working with wholesalers mean giving up product control?

Using a wholesaler usually means limited customization. Their focus on volume and efficient inventory means it’s hard for importers to get niche, seasonal, or unconventional products through this channel.

Wholesalers want fast turnover and simple warehouse management. They carry just enough core items to move quickly. I realized that if I only used wholesalers, my range stayed small and predictable. Customers who wanted special or differentiated products left for other sources. Still, the stability was valuable for basic, high-volume SKUs.

Wholesaler Distributor Disadvantage Table

| Disadvantage | Why It Happens | Importer Impact |

|---|---|---|

| Limited Options | Focus on core SKUs | Few custom products |

| Slow to Add New Items | Bulk management | Late response to trends |

| Irregular Niche Support | Warehouse simplicity | Cannot meet unique needs |

Why is there a discrepancy between wholesale and retail prices?

Why do wholesale prices differ from what retailers pay consumers?

Wholesale prices are lower because wholesalers handle bulk storage, inventory financing, and logistics risk. Markups cover these costs, so retail prices reflect the added operational layers.

As an importer, I saw wholesalers take on big risks—buying shipments in bulk, tying up capital, managing stock through ups and downs. Their markup isn’t just profit; it’s a buffer for the challenges of moving large volumes and absorbing uncertainty before selling to smaller buyers. Retailers then add their own costs, making the consumer price much higher.

Wholesale vs. Retail Price Table

| Cost Factor | At Wholesaler Level | At Retailer Level |

|---|---|---|

| Bulk Inventory Finance | High | Low |

| Warehousing | Large scale | Small scale |

| Risk Absorption | Major (stock loss/demand) | Minor |

| Distribution Logistics | Full pipeline | Last-mile only |

| Total Markup | Covers all above | Adds store overhead |

What are the main problems of distribution?

Why does the distribution process create tension between wholesalers and importers?

Distribution problems come from misaligned incentives—wholesalers want speed and volume, importers want flexibility and agility. Other issues include supply chain delays, inventory risk, and poor information flow.

When I worked with big wholesalers, their systems always pushed bulk movement. This left me waiting when I needed quick changes or smaller, custom shipments. Communication breakdowns sometimes caused delays, costing me time and sales. I started using a mix of partners: wholesalers for core items, nimble firms for custom or niche goods. This balanced reliability and adaptability in my supply chain.

Distribution Problems Table

| Main Problem | Description | Importer Solution |

|---|---|---|

| Incentive Misalignment | Wholesalers push volume, importers want options | Use wholesalers for basics, diversify for niche needs |

| Lack of Flexibility | Slow to respond to change | Build flexible partnerships |

| Inventory Risk | Wholesaler absorbs, importer delays | Share inventory data, find shared solutions |

| Communication Gaps | Delays in orders/info | Regular updates, integration tools |

Conclusion

Wholesalers run lean catalogs to support volume, efficiency, and reliable supply. While this limits flexibility for importers, it stabilizes prices and service. The real solution is not fighting the approach, but using wholesalers for core items and adding flexible partners for niche needs. By building a diversified portfolio of supplier relationships1, importers combine the best of both worlds—streamlined bulk orders2 and agile sourcing to remain competitive. Smart importers don’t chase absolute control; they design a supply chain that balances efficiency with adaptability.