What Causes Delays in Offshore Stationery Supply Chains

Everyone fears late shipments, but with offshore stationery, uncertainty is the real pain. Lost in the handoff between partners, delays emerge, leaving importers frustrated, customers unhappy, and costs rising.

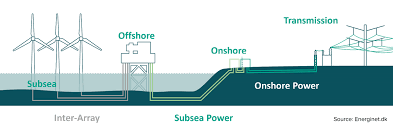

The main cause of supply chain delays is fragmented communication between factories, logistics, and customs. When information does not flow smoothly, every stage risks extra waiting, missed shipments, and longer lead times.

As someone who manages international orders often, I call this the “black box” effect. You send your order, then silence. Updates are rare or vague. When something stalls—like a missing document or late cargo—the news often comes too late to act. This uncertainty breaks trust with customers and makes it impossible to plan or promise accurate arrival dates. Let’s unravel the most common pain points, so you can spot delays before they hit.

What is the main reason for shipping delays?

Why do shipments from overseas factories end up late?

The most common reason is missing paperwork or incomplete customs documentation. Even small mistakes here can hold entire shipments for days or weeks.

I’ve seen a single missing signature on a customs form trap a container on the docks. Because multiple parties must provide updates, mistakes easily slip through. When everyone from the supplier to the freight forwarder is involved, one misstep blocks the whole line. That’s why centralized tracking and proactive document checks are crucial in preventing costly holdups.

Shipping Delay Causes Table

| Reason | How It Delays Shipments | How to Prevent |

|---|---|---|

| Incomplete Documents | Customs won't clear cargo | Pre-check all paperwork |

| Port Congestion | Waiting to unload/load | Choose less busy ports |

| Vague Handoffs | Shipments missed or late | Confirm clear partner roles |

| Poor Coordination | Missed vessel bookings | Close communication chain |

What are the three most common problems with supply chains?

Which repeated failures stop offshore stationery from reaching its destination on time?

The three most common problems are poor communication, inaccurate inventory data, and unpredictable logistics disruptions. Each adds delays and makes planning harder.

In my experience, factories often send updates late or not at all, so importers rely on old information. Inventory errors arise when what’s promised doesn’t match what is ready to ship. Finally, global events—like strikes or weather—throw off even the best schedules. The key is not just better tracking tech, but regular check-ins between everyone in the chain.

Common Supply Chain Problems Table

| Problem | Why It Happens | Fix/Improvement |

|---|---|---|

| Weak Communication | Siloed teams/geography | Shared update platform |

| Bad Inventory Data | No single source of truth | Sync real-time data across sites |

| Disruptions Unmanaged | No backup/resilience plan | Flexible contracts, risk plans |

What are the root causes of material delivery schedule inaccuracy in supply chains?

Why are material delivery predictions so often wrong?

Material schedule issues often stem from demand planning errors, sudden production hiccups, and slow feedback when something changes. These factors make ETAs unreliable.

Orders start with a rough idea of demand, but it changes quickly. Even small glitches like a machine break at the factory can throw off timelines. If forwarders or third-party agents discover issues late, updates are slow to reach importers. From my own projects, I’ve found reviewing schedules weekly and using direct messaging tools shortens notice times and smooths out hiccups.

Material Delivery Inaccuracy Table

| Root Cause | Effect on Delivery | Practical Solution |

|---|---|---|

| Bad Demand Forecasts | Missed or excess orders | Rolling demand review cycles |

| Production Delays | Entire batch late | Immediate escalation channels |

| Delayed Updates | No time to reroute/resolve | Automated milestone alerts |

| Shipping Bottlenecks | Final step slows everything | Real-time port status tracking |

Conclusion

Delays in offshore stationery supply chains1 are rarely caused by one big mistake—they’re the result of small breakdowns in communication, documentation, and visibility. Lacking a “single version of the truth,” importers struggle to manage each step, leaving them blind when something goes wrong. I’ve seen firsthand how these gaps cause missed vessels, lost opportunities, and shaky customer relationships. The answer is not only tech, but teamwork—bridging the “black box” by sharing updates and holding all partners accountable. Better forecasts, faster escalation when issues appear, and shared dashboards2 all help cut delays. For importers, fixing these weak links means smoother shipments, happier customers, and more predictable profits in a fast-moving world.